1. Introduction: The emergence of Knitted Tape

1.1 Concept and application background of Knitted Tape

Knitted Tape is a strip material made by textile weaving technology, which has good flexibility, strength and aesthetics. It shows extremely high plasticity in appearance design and functional performance, and is widely used in clothing, industry, electronics, cables, automobiles, medical and other fields. With the growing demand for lightweight and high-strength materials in modern manufacturing, Knitted Tape has gradually stood out due to its unique structure.

1.2 Why is Knitted Tape so popular?

The reason why Knitted Tape has attracted attention from major industries is due to its excellent comprehensive performance: stretchability, breathability, wear resistance, decorativeness, etc., and the production process is controllable and the cost is moderate. It can provide composite properties that traditional materials cannot achieve, becoming a model of material innovation, especially suitable for product demand scenarios with complex shapes and multi-functions.

2. Unique advantages of Knitted Tape

2.1 Superior strength and durability

Knitted Tape adopts circular weaving technology to bring excellent mechanical properties. Its weaving structure can effectively disperse external forces and cope with extreme use conditions such as high-frequency bending, stretching and friction. Especially in industrial use, its durability becomes a key advantage.

Strong tensile performance: Compared with ordinary webbing, the structure of Knitted Tape can achieve a higher degree of tensile resistance.

Long wear resistance and life: Suitable for high-wear environments, such as luggage fixing straps, outdoor equipment straps, etc., to extend the service life.

2.2 Good flexibility and plasticity

Knitted Tape maintains high elasticity while having excellent bendability, which can adapt to the installation or covering needs of various irregular shaped products.

Multi-directional ductility: Not easy to twist and deform, suitable for complex structural components.

Strong morphological controllability: Easy to operate, cut and sew in the design.

2.3 Good air permeability and moisture absorption

Due to the tiny pores between Knitted Tape, it can effectively realize the exchange of air and moisture, which is very suitable for applications that require heat dissipation and drying.

Reducing heat accumulation: It can be used to cover the outer layer of the equipment to assist in heat dissipation and cooling.

Moisture-proof protective parts: It can effectively prevent moisture accumulation from causing equipment aging or corrosion.

2.4 Aesthetics and design flexibility

Knitted Tape has rich colors and customizable patterns, which is suitable for scenes that pursue beauty, such as high-end clothing accessories, sports products, luggage decoration, etc.

Rich visual effects: There are many optional materials, which can present different effects such as matte, glossy, and silky.

High design compatibility: It is easy to match and combine with a variety of materials such as plastics, metals, and fabrics.

2.5 Efficient production process and cost-effectiveness

With the popularization of automated knitting equipment, the production efficiency of Knitted Tape has been greatly improved, which is particularly suitable for mass production. Its wide range of raw materials makes it have a good cost-effectiveness.

Low scrap rate: The automated production process is precise and reduces the waste of raw materials.

Adapt to multiple specifications: width, density, and elasticity are all adjustable, suitable for customized orders.

3. Wide application of Knitted Tape in various industries

3.1 Application in the textile industry

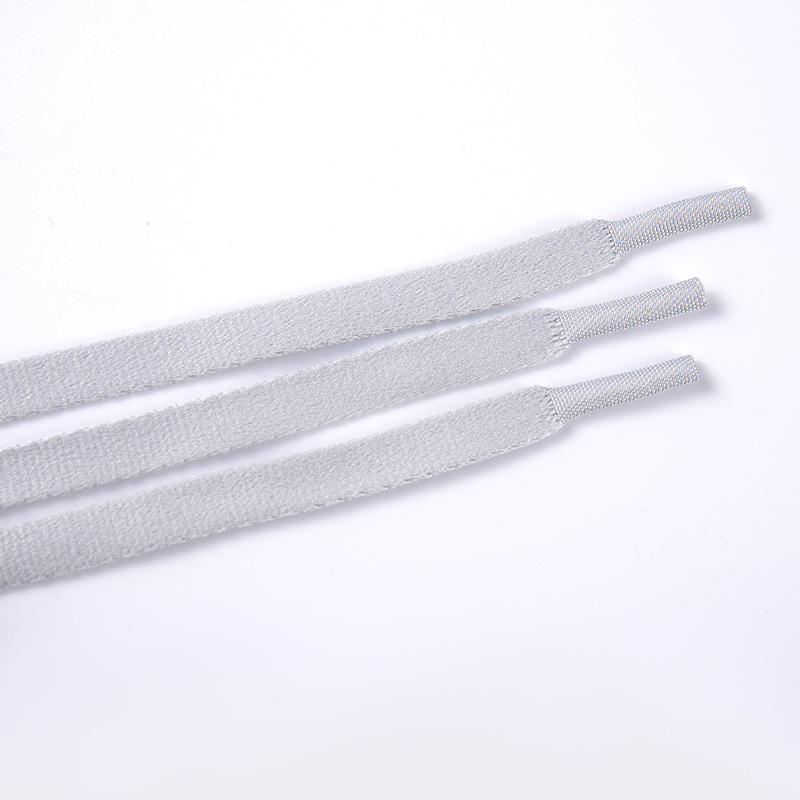

Knitted Tape plays a dual role of functionality and decoration in the field of clothing and footwear.

Garment decorative tape: widely used in sportswear and outdoor clothing to enhance brand recognition and practicality.

Shoelaces and shoe edge edging: provide a comfortable touch and enhance structural stability.

3.2 Application in the automotive industry

Automobile manufacturing has high requirements for the temperature resistance, wear resistance and aesthetics of materials.

Wire harness coating: Knitted Tape is used for the binding and protection of cable harnesses to prevent vibration and wear.

Carriage decoration: used for door edges, dashboards and other parts to enhance the texture and practicality of the car.

3.3 Application in electronic products

Modern electronic equipment pursues lightweight, good heat dissipation, anti-interference and other properties.

Winding protection: used for the outer layer of the cable, with heat insulation and anti-electromagnetic interference functions.

Heat dissipation assistance: Knitted Tape helps airflow and heat dissipation on high-power modules or housings.

3.4 Application in the packaging industry

Knitted Tape is increasingly used in high-end products and customized packaging to enhance the overall texture.

Gift box trim: Enhance the artistic and high-end feel of the packaging.

Packaging straps: Give the packaging softness and recyclability while maintaining strength.

4. How to choose the right Knitted Tape?

4.1 Choose the right specifications and materials according to product requirements

When choosing Knitted Tape, you need to select the material, weaving method and functionality according to the specific product usage scenario.

Material differences: Common materials such as polyester, nylon, cotton yarn, etc. should be selected according to the requirements of heat resistance, wear resistance and moisture resistance.

Functional requirements: If it needs to be flame retardant, UV resistant, corrosion resistant, etc., the functional tape should be selected in combination with product requirements.

4.2 Ensure the accuracy of the production process

Although Knitted Tape is a flexible material, the accuracy of its process is directly related to the performance of the product.

Knitting density control: The appropriate density should be set according to the requirements of tension and expansion ratio.

Dimension consistency detection: Inspection standards should be used to control the consistency of width and elasticity during mass production.

5. Future Outlook: Innovation and Development of Knitted Tape

5.1 Promotion of Technological Innovation

With the development of new fiber materials and intelligent manufacturing technology, Knitted Tape will move towards higher performance and more intelligent direction.

Smart yarn application: In the future, conductive or sensing functions can be added to achieve intelligent control.

Environmentally friendly material development: Degradable and recyclable materials will become a trend to meet the needs of sustainable development.

5.2 Continuous expansion of application areas

In addition to traditional industries, Knitted Tape also has great potential in special industries such as medical, aviation, and military.

Medical fixation belt: used in medical devices, rehabilitation aids, etc., with both comfort and stability.

Military equipment: Special Knitted Tape with radiation resistance and high temperature resistance will be widely used in high-risk environments.

6. Conclusion: The unique value of Knitted Tape

Knitted Tape is redefining the value of tape materials with its unique weaving structure and versatility. From functionality to aesthetics, from industrial to consumer products, it brings reliability, innovation and added value to all kinds of products. With the evolution of technology and the diversification of demand, Knitted Tape will continue to play an irreplaceable and important role in future manufacturing, providing a continuous driving force for product innovation and industry progress.

English

English 中文简体

中文简体