1. Advanced Weaving Technologies: The Foundation of Superior Nylon Knitted Bands

1.1 Precision-Controlled Automated Weaving for Consistent Quality

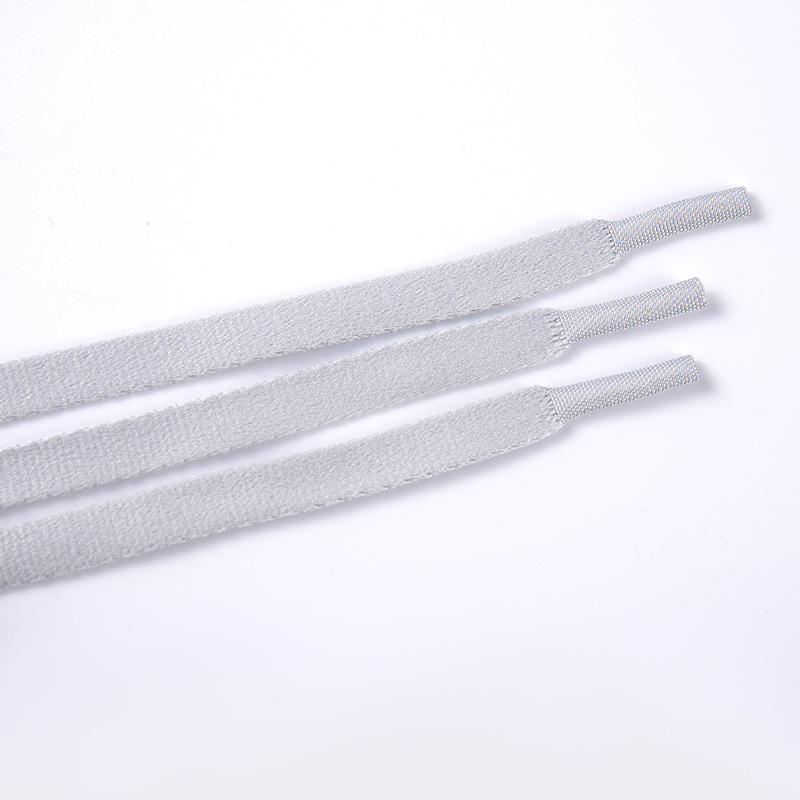

China wholesale nylon knitted bands suppliers utilize state-of-the-art automated weaving machines capable of precise fiber placement. This level of accuracy ensures each band maintains optimal strength, flexibility, and abrasion resistance, which are critical for industrial applications demanding uniform product performance.

1.2 Tailored Textile Structures to Meet Diverse Customer Needs

By adjusting weaving density, texture, and fiber arrangement through advanced machinery, suppliers can customize nylon bands to cater to different industries—from high-strength industrial belts to flexible, wear-resistant fabrics—ensuring each batch aligns with specific client requirements.

1.3 Minimizing Human Error to Guarantee Product Consistency

Automation reduces manual intervention, significantly decreasing variability caused by human factors. This technological advantage leads to batch-after-batch consistency, empowering manufacturers to uphold strict quality benchmarks and enhance customer trust worldwide.

2. Comprehensive Quality Control: Ensuring Reliability from Raw Material to Finished Product

2.1 Rigorous Raw Material Selection for Durability and Performance

Suppliers source only premium-grade nylon fibers screened for superior tensile strength, environmental resilience, and wear resistance. This stringent selection forms the backbone of the final product’s durability and long-term performance under demanding conditions.

2.2 End-to-End Monitoring and Process Control

Throughout production—spanning weaving, dyeing, and molding—suppliers implement real-time monitoring using automated control systems. This continuous oversight allows immediate correction of deviations, ensuring all nylon knitted bands strictly comply with quality specifications.

2.3 Advanced Final Product Testing to Guarantee Standards

Before shipment, each batch undergoes comprehensive testing protocols, including tensile strength, abrasion resistance, and color fastness assessments. Utilizing sophisticated testing apparatus ensures that only products meeting or exceeding industry standards reach customers, significantly mitigating the risk of quality failures in the field.

3. Automation and Innovation: Driving Efficiency and Market Competitiveness

3.1 Fully Automated Production Lines Enhance Efficiency and Output

China’s nylon knitted band manufacturers employ fully integrated automated production systems that accelerate manufacturing speed while maintaining exacting quality standards. This approach enables quick scaling of orders without sacrificing product integrity.

3.2 Consistent Quality Control Through Reduced Human Intervention

Automation not only boosts efficiency but also stabilizes product quality by limiting the chance of human-induced errors. Every production stage—from weaving density to post-processing—is tightly regulated by machinery, ensuring uniformity and reliability.

3.3 Fast Turnaround Times Supporting Global Supply Chains

The streamlined automated process shortens production cycles, enabling suppliers to meet tight deadlines and large-volume demands. This agility helps global buyers maintain steady supply chains and minimize disruptions caused by delays or inconsistent product quality.

English

English 中文简体

中文简体